injection molding Service

We provide turnkey service from mold design, mold making to plastic injection molding service

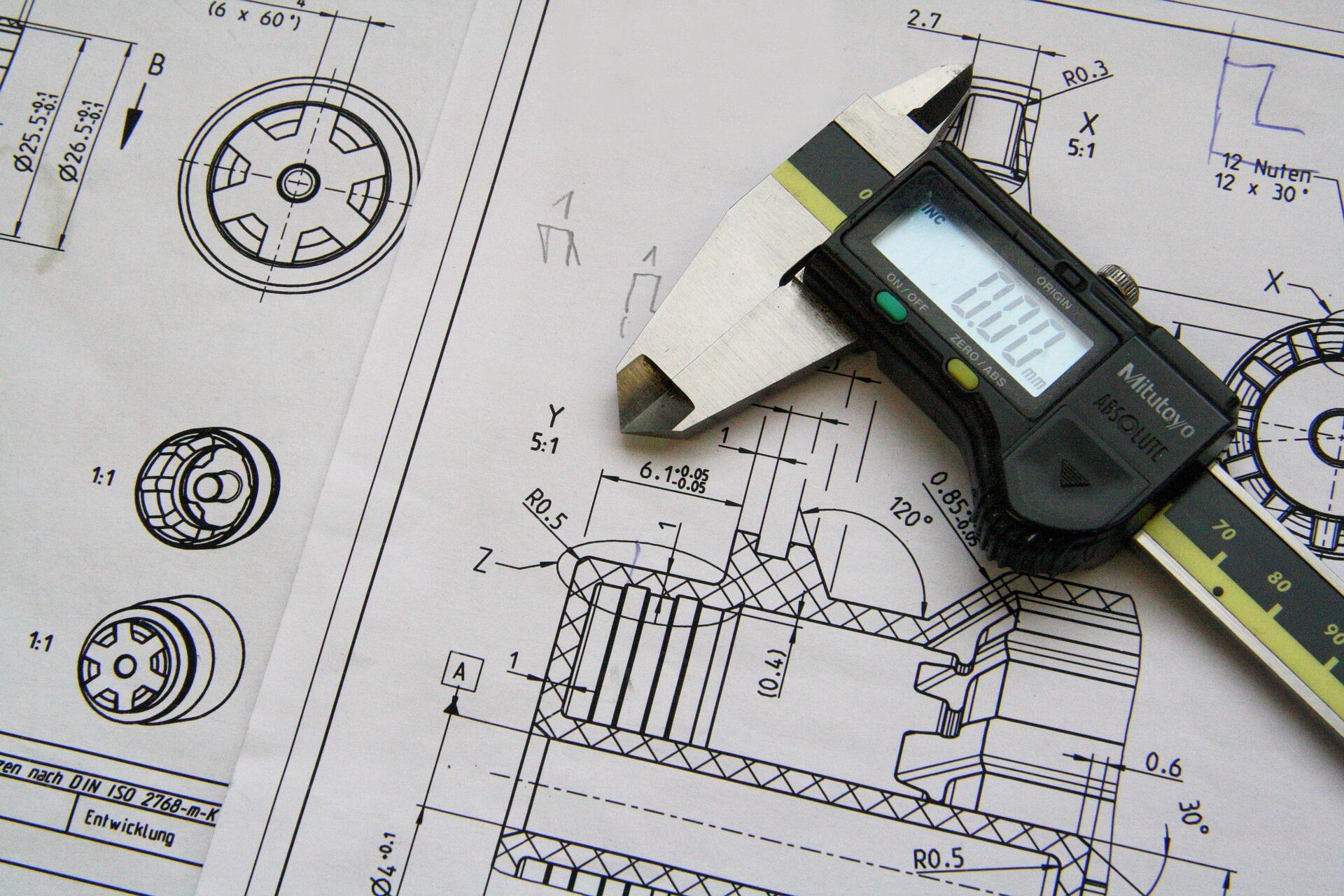

Mold Design

Mold designers use CAD software to design the injection mold for the plastic products. They check the shrinkage rate, size and geometry of the injection molded parts.

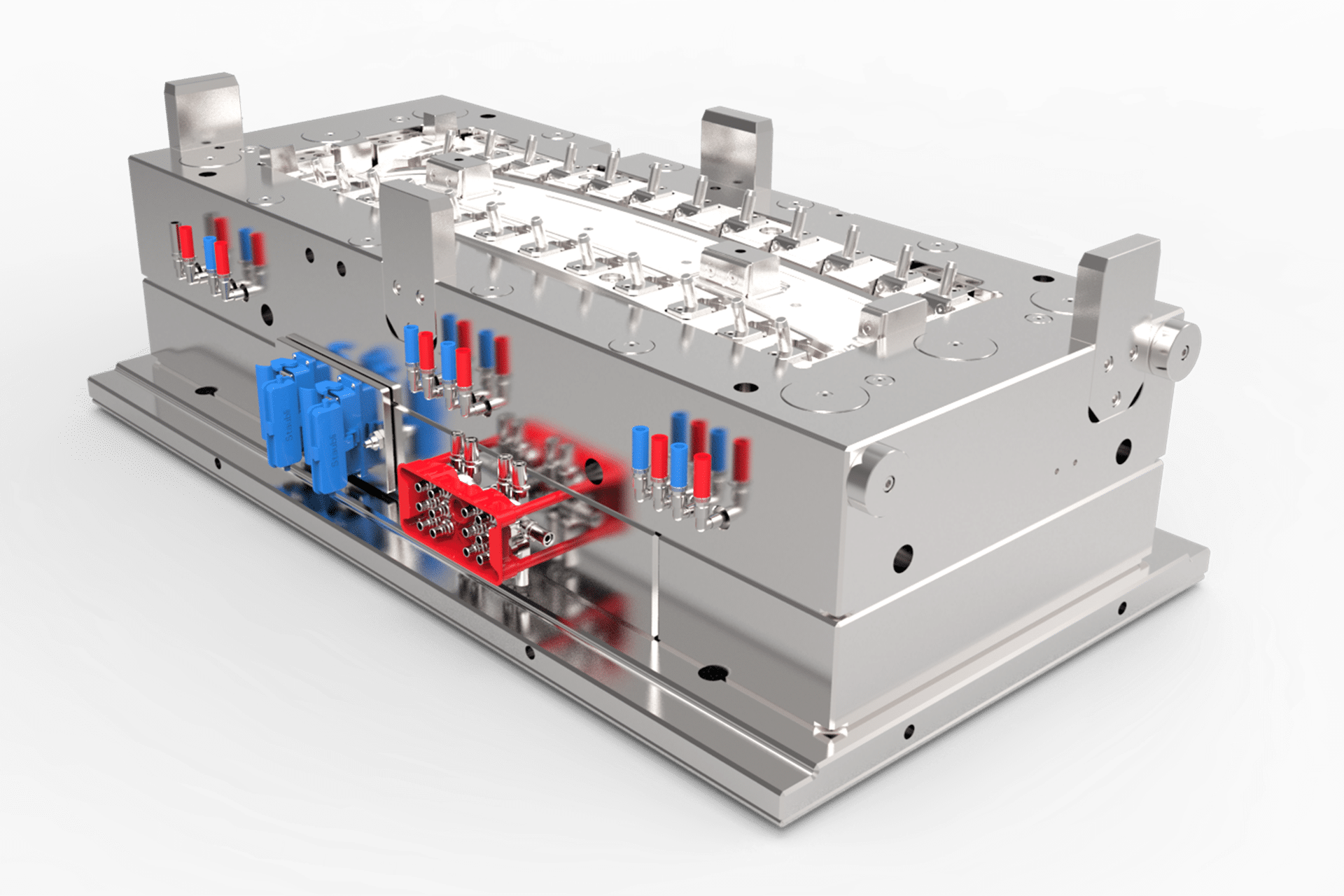

Mold Making

Mold makers machine mold components designed by mold designers and assembly them together. The components are high precision steel parts made by cnc machines.

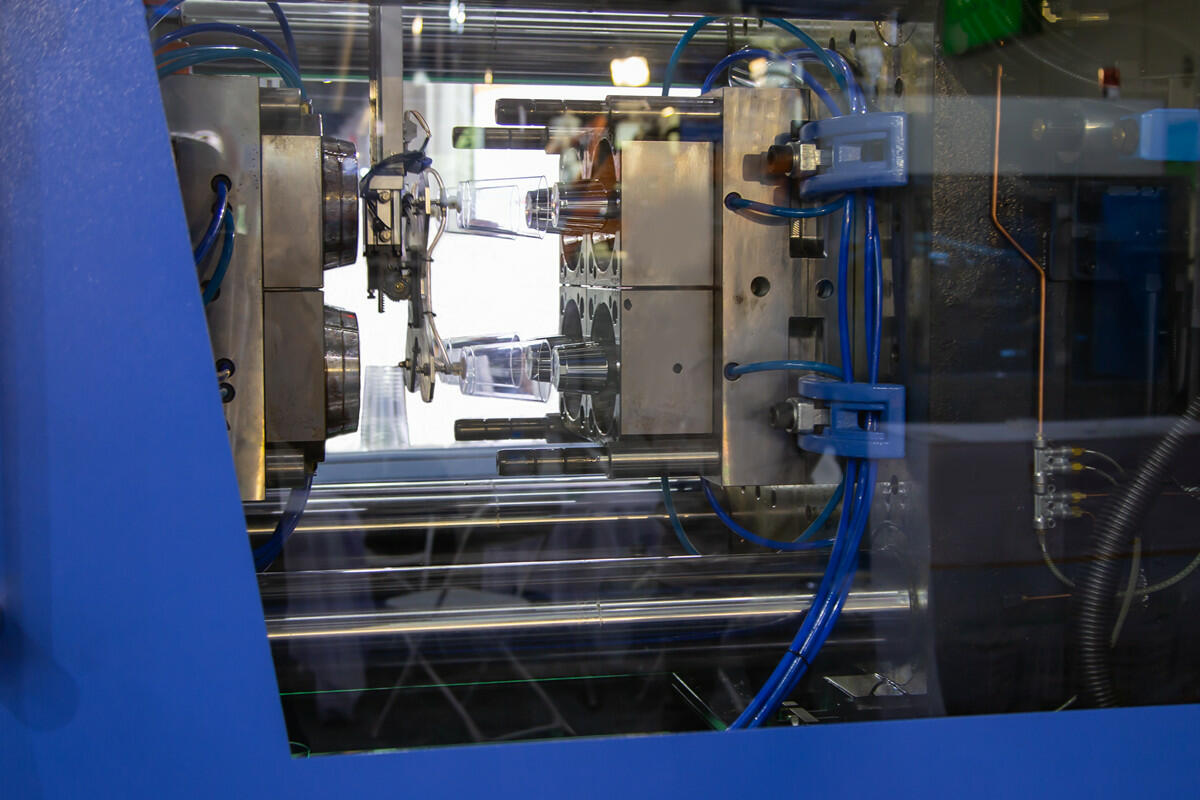

Injection Molding

Injection molding is processed on injection molding machines. The injection mold is mounted on the machines and molten plastic flow is injected into the mold cavity to form the plastic parts.

Injection Molding Finish

| Materials | Color | Description | |

|---|---|---|---|

| Smooth | ABS PC PE PP PMMA PS | ALL colors | Polish the mold cavity to #1200 sand paper to make parts surface smooth. |

| Painting | ABS PC PE PMMA PS | All colors | Spray a layer of paints on the surface of the products to protect them and make them look better. |

| Silk Screen | Most common plastic | All colors | Print the logo, words or patterns on the surface of the products by silk screen. |

| Plating | ABS, PC | All colors | Electronical plating makes the product look shining. The shining layer is chrome. |

Injection Molding VS Rapid Prototyping

Injection molding is used for large quantity production while rapid prototyping for low volume production.

- Injection molding offers low unit price but high cost injection mold, rapid prototyping makes parts without mold.

- Injection molding produces thousands of products in several days, more efficient than rapid prototyping.

- We start injection molding after confirmation of final products and rapid prototyping at the stage of product design and development.

- The strength of injection molded parts are higher than prototypes.

- There will be gate residue, pin mark, parting line on the injection molded parts, and prototypes don’t have these.