Rapid Prototyping Service

We use rapid prototyping, cnc machining, vacuum casting technology to make the prototypes in a short time

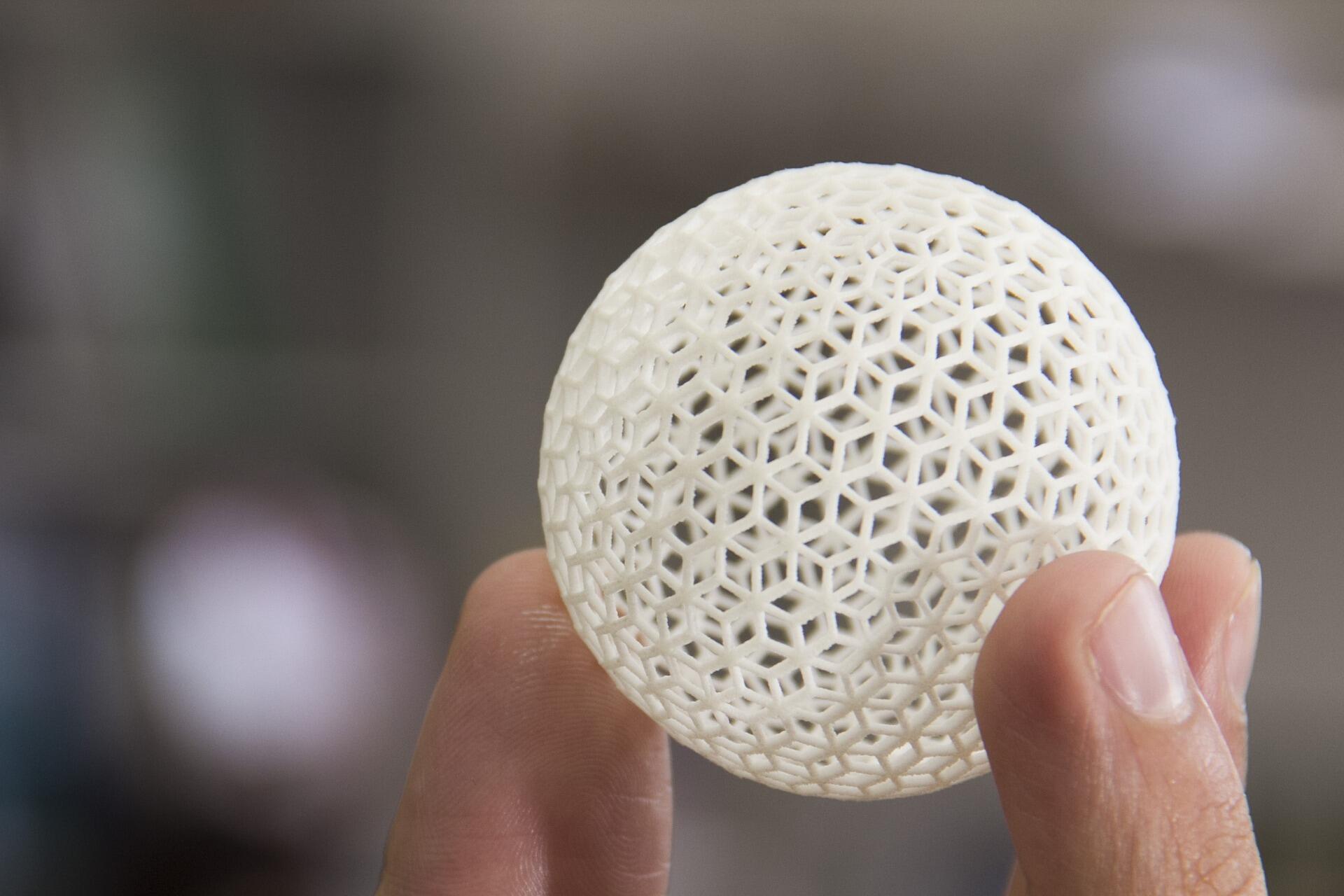

3D printed Prototype

3D printing technology is used to make the prototypes by adding material layer by layer. Suitable for low volume production of plastic parts.

CNC Machined Prototype

CNC machining technology make the parts by reducing the material from blocks or rods. Suitable for low volume production of plastic or metal parts.

Vacuum Casting

Vacuum casting technology makes the prototypes by adding liquid to silicone molds. Suitable for low volume production of plastic or rubber parts.

Rapid Prototyping Finish

| Materials | Color | Description | |

|---|---|---|---|

| Polish | All plastics and metals | No | 3D printed or cnc machined prototypes have some marks on the surface, in order to make smooth surface, we will polish them to get rid of the milled or printed marks. |

| Painting | All plastics and metals | All colors | Spray a layer of paints on the surface of the prototypes to protect them and make them look better. |

| Anodizing | Aluminium | All colors | Oxidate the surface of aluminium and form a layer of oxide to protect the aluminium prototypes from eroding. |

| Silk Screen | Plastics, metals and rubbers | All colors | Print the logo, words or patterns on the surface of the prototypes by silk screen. |

| Plating | ABS, PC, Aluminium, Steel | Silver | Electronical plating makes the prototypes look shining. The shining layer is chrome. |

How To Choose The Tech

Each technology has its own pros and cons, every designer could choose the best production way suitable for his project.

- Want to see the reality of your design or verify the concept, choose 3d printing.

- High requirement of tolerance, choose cnc machining.

- Quantity bigger than 10, choose vacuum casting.

- Metal material, choose cnc machining.

- High strength prototypes, choose cnc machining.

- Silicone or rubber prototypes, choose vacuum casting.

- Want to save cost, choose 3d printing.