Some common injection molding terms.

Just like the other industrial engineering business, plastic injection molding has its own technical terms. Here are some most frequently-used technical terms we may meet on mold making and plastic injection molding.

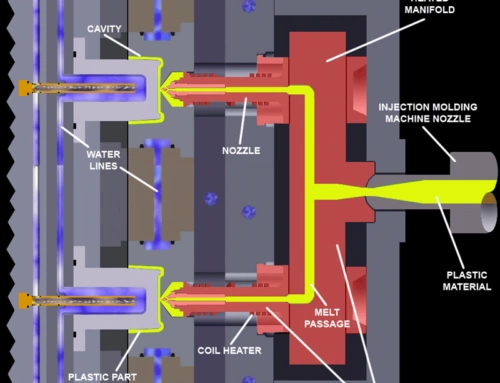

Gate

Gate is a special entrance connect the runner and the cavity. If there is no gate, the runner will connect with the part directly. It would be very hard to remove the runner from the part. So we need to design a tiny, thin gate to connect the runner and part and this gate should be easy to be removed. There are various gate types and the mold designer will choose the right gate type according to the geometry and surface requirement of the product.

Runner

Runner is the channel where the molten plastic flow was injected and flow along into the gate and cavity. There are two types of runner system, hot runner and cold runner.

Ejector Pin

After the part was formed inside the cavity, the mold should open and eject the formed part out. The components push the parts out of the cavities are ejector pins. The ejector pins are straight, round or square and fixed on the moving half of the mold. Sometimes the ejector pins move in a oblique way, which are called angle pins. Some products with undercuts need angle pins.

Parting line

Plastic mold could be divided into two halves, the fixed half and the moving half, also we could call them the cavity side and the core side. Parting line is where the moving half contact the fixed half. The mold designer should determine where the parting line locate according to the part. Parting line also means the line mark on the contacting face between the moving half and the fixed half.

Draft

Due to the part is ejected from the cavity, there has to be a draft angle for the part to be ejected smoothly. The side wall, ribs and bosses must have draft angle. The draft angle means the bottom has to be a little bit bigger than the top, which could help the part to be ejected smoothly.

Fengjin Mold is a professional plastic injection molding company provide mold design, mold making and plastic injection molding services, if you have any inquiries, please contact sales@fengjinmold.com