High quality mold or low quality mold, what is the difference?

Like all the other commodities or business service, you could meet high quality mold suppliers and low quality mold suppliers. But no one will admit that they are selling the inferior plastic molds, but using the competitive price mold instead. Then what is the difference between the high quality plastic mold and the low quality one?

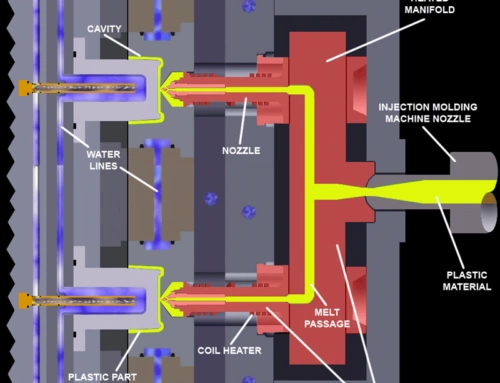

Mold simulation

High quality plastic mold will do mold flow simulation or other similar simulation to see what problems may happen and find the solutions. The simulation could be made by CAD and CAM software. These software could help mold designers to avoid the future defects by simulating the mold flow, the heat environment and the cooling system working situation.

Simulation CAD and CAM software is quite expensive, it would be a big investment for the injection molding company. This process would improve the plastic mold quality, but increase the cost.

Low quality supplier won’t do this and can’t avoid the potential defects on the stage of mold design. They can save the plastic mold cost with no need to purchase the expensive CAD and CAM software.

Branded mold base

High quality plastic mold suppliers use the branded mold base which is made by the world famous mold components manufacturer. The famous brands include, DME, HUSKY, YUDO, LKM etc.. The branded mold base has higher precision and better strength, although the high cost.

Mold base is a very important component for making a high quality mold. All the other components, the mold core and cavity, ejector pins, plates, and sliders or lifters must be fixed on the mold base. The mold base could determine the precision and quality of the final plastic molded part.

Low quality suppliers use the inferior mold base, or make the mold base by themselves, or don’t use the mold base.

Mold core and cavity material

High quality plastic mold suppliers use special stainless steel to make the mold core and cavity. The stainless steel molds have a high mold life which could last more than 500,000 shots. High quality material could reach the high precision and good surface effect.

Low quality suppliers use inferior mold core and cavity material, which only last several thousands of shots. The precision and surface effect are also low.

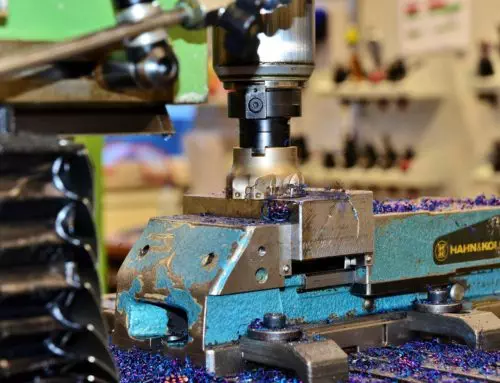

Machining Cost

High quality plastic mold suppliers use high precision machining machines to make the mold core, cavity and other components, for example, the high speed cnc machining tools, EDM machines, grinding machines and so on.

Low quality suppliers would like to save the machining cost and use the normal milling machines. So the machining cost would be quite low.

In summary, high quality mold could bring high quality plastic molded products. But choosing the high quality mold or low quality mold depends on your real demand.

Fengjin Mold is a professional plastic injection molding company provide mold design, mold making and plastic injection molding services, if you have any inquiries, please contact sales@fengjinmold.com