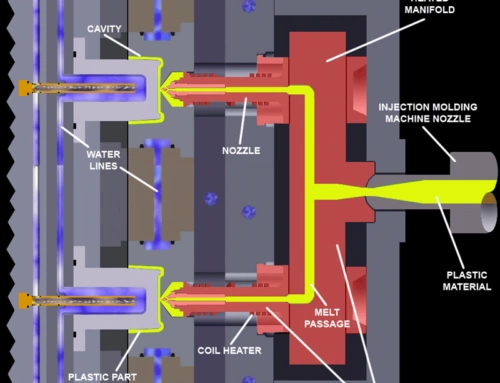

Benefits of Robotic Arm in Plastic Injection Molding.

Nowadays, when the labor cost is raising, more and more plastic injection molding companies in China are utilizing robotic arms to improve the efficiency and save the cost. Robotic arms could help to take the parts out from the injection molding machine and put them softly on the conveyors. There are lots of benefits from the utilization of robotic arms.

1. Improving the efficiency

The robotic arms take the plastic injection molded parts out and remove the runners from the final products. It takes much more time for the human to finish the take-out and runner removal processes. The conveyors carry the finished parts together for the worker to do the followed processes. The robotic arms could make the plastic injection molding production much more efficient than traditional production.

2. Saving the cost

Robotic arms could help to reduce 2/3 labor cost for production. And the cost of robotic arms are also lower than the salary of the human workers. Robotic arms could help plastic injection molding company hire less people and get more output.

3. Nonstop Production

Robotic arms need no rest, which could continue to work without interruption. Utilization of robotic arms could make the plastic injection molding factory run 24/7, resulting the short lead time for production.

4. Protection of Products

For some high cosmetic finish products, the outer surface is very easy to be scratched. Robotic arms take the products out by the silicone sucker and put softly on the conveyors, which could protect the parts finish from being scratched or damaged.

Fengjin Mold is a professional plastic injection molding company provide mold design, mold making and plastic injection molding services, if you have any inquiries, please contact sales@fengjinmold.com