What impacts an injection mold cost?

When a plastic injection mold purchaser is collecting the quotations, they will find that the quote could vary from an extreme low price to a relative quite high cost. The mold is so important, it must be made most suitable for your project, the price can’t beyond the budget and the quality should be as the expectation. But why there is a so big difference on plastic injection mold market? How to find the right plastic mold and injection molding supplier? Let’s see what impacts an injection mold cost.

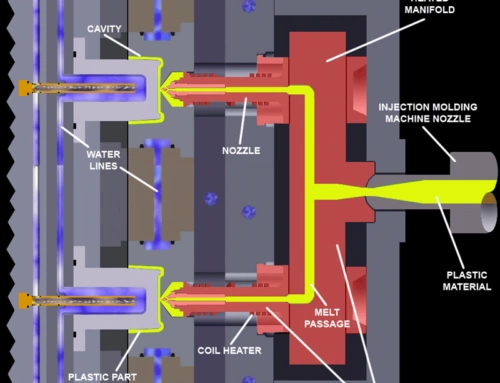

The injection mold is an assembly combined by many components, the mold base, cavity, core, ejector, runner, gate, sometimes we need to add lifter or slider if there are undercuts on the product. We can analysis the mold cost from these components to understand why the mold price could be so different from different injection molding suppliers.

1. Mold Base

Mold base can be thought as a “base” contains all the mold components, like the cavity core, ejector and other things. Most of mold bases are standard and made by some famous mold base manufacturer. The price is different depending on the different supplier. For example, DME mold base is much higher than LKM. The mold base could account about 1/3 of mold cost. The better mold base brand, the higher mold price.

2. Core and Cavity Material

Generally, the core material is steel. Sometimes, the supplier will use aluminium to make the prototype mold for a short run production. But for the long run production, the mold core material should be steel harden by heat treatment. The machining cost will go higher for harden steel material. The harden steel mold core > normal steel core > aluminium core. When we choose the harden steel mold core, we have another purpose which is to make a high precision and high glossy product.

3. Runner Type

There are two types of runner, cold runner and hot runner. Some high requirement product will utilize hot runner to make the flow more smooth. Cold runner is made on the core and cavity, so it will not add extra cost. The hot runner is a exterior component fixed on the mold. Hot runner is a standard component too. The manufacturer supplies mold base also supplies hot runner. So the price is different from different hot runner suppliers. The better hot runner, the higher price.

4. Number of Cavities

Actually, the number of cavities depends on the annual demand of the product, the more cavities, the lower unit cost, but higher mold cost. The purchaser has to negotiate with the plastic mold supplier to confirm the number of cavities and choose a most suitable plan for the project.

5. Number of sliders and lifters

Although the injection molder won’t suggest the product design to use many undercuts structure, but some products do require undercuts. In order to make the undercuts, we have to use lifters or sliders which are moving components inside the mold to shape the undercuts and move away to make the part be able to be ejected. A slider or lifter could cost from $100 to $300. The more sliders, the higher mold cost.

Fengjin Mold is a professional plastic injection molding company provide mold design, mold making and plastic injection molding services, if you have any inquiries, please contact sales@fengjinmold.com